SG#051

Equipped as follows:

- Six color offset press with coater

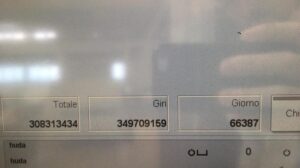

- Circa 308 million impressions

- Prinect PressCenter

- Press Center MasterLevel

- Press Center Instant Gate

- Press Center WallScren

- Prinect Inpress Control

- Preset Pus Feeder

- Ultrasonic double-sheet control

- Multiple-sheet detector/ tear-off

- Multiple sheet control/Forwarding roller

- Double sheet detector – pulling device

- StaticStar Compact

- Roller wash-up device controlled by Prinect Press Center

- Blanket and impression cylinders automatic washing devices with cloths by Prinect Press Center

- Hycolor damping + Vario system

- Air Transfer System Venturi

- Autoplate Advanced. Semi-automatic plate change

- 2 x LED UV interdeck dryer mod. Lp medium power (8W) movable between all units

- 2 x LED UV interdeck dryer mod. Q high power (18W) movable between 2°, 3° and 5° units

- No. 1 LED UV interdeck dryer mod. M high power (26W) on 6° unit

- Varnishing units 550 L./H. with Tresu chambered doctor blade system and anilox roller and diagonal register remote control

- LWE roller storage coating unit facility

- Preset Plus Delivery: a lot of preset functions and memorization

- Aereodinamic grippers system

- Slow down system by console

- Panel in delivery

- DryStar 3000 Combination 3 slide-in dryers

- CanOpen: no. 1 dryer slide-in unit IR/HA air knives

- PowderStar Weko AP 500

- Extended Delivery X2

- Sheet slow-down device suction drum 9 mm

- Non-Stop delivery automatic version

- Intercom system: Microphone communication system

- No. 1 LED UV interdeck dryer mod. M high power (26W) on delivery

- ScrollStar: Atlas Copco compressor

- AirStar Pro: central air box water cooled

- Speed: 18.000 speed/hour