NO LONGER AVAILABLE.

SG#091

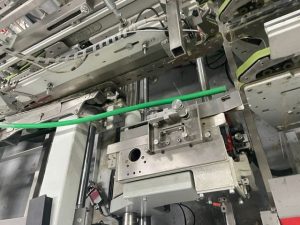

Equipped as follows:

- Max Blank Width 1100 mm

- Min Blank Width 126 mm

- Max Blank Length 800 mm

- Min Blank Length 60 mm

- Max Speed 20 – 350 m/mm

- Special Plastic KIT for laminated board PE, metalized materials and varnished board

- Working hours only 4000!!!

- Code Reader HHS

- Glue line detector HHS

- Lock bottom

- 4 point corner gluing device

- Type of system: Xtend2 cold glue QA (Quality control)

- HHS electronic upper gluing system with 4 guns

- Lower disc gluing system left

- Pre breaker right and left

- Kicker

- Counter

- Feeder

- Blank aligning device available

- Set up quickly and rapidly

- Variable speed independent drive

- Adjustable on the run

- Easy repeatability

- Light maintenance

- Feeds most types of materials

- Handles most box styles

- Prebreaker

- 180° prebreaking of all boxes at

- High-speed, regardless of material

- Long prebreaker for perfectly flat

- Glue flaps

- Extra wide lower left-hand belt ensures

- No marking

- High-speed re-opening plough

- Upper left conveyor displacement

- Crash-lock module

- Processes multiple-fold packaging

- Prebreaks large boxes and provides a location for supplementary devices such as label inserters

- Telescopic upper conveyors easily be adjustable to box format

- Allows for front panel folding

- Folding

- Minimum folding device for folding down to 35 mm

- Choice of left, right or simultaneous folding

- Automatic belt tensioning ensures quicker makeready transfer

- Independent drive for complete control and faster job change

- Synchronized kicker adjusts to carton arrival time

- Adjustable transfer conveyors adapt to difficult box shapes

- ACCUEJECT or rotary ejector device ejects non-conforming boxes

- Height adjustable for a perfect box stream

- Materials specs: carton or solid board, up to 800 g/m², Corrugated board N–F–E N–F–E <> Thickness of folded box, max. 12 mm