NO LONGER AVAILABLE.

SG#105

Equipped as follows:

- 8-up five color offset press

- 28 x 40

- Circa 71 million impressions

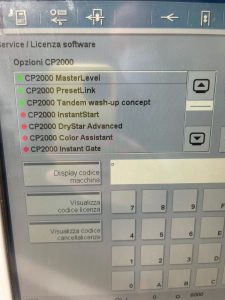

- CP 2000 console touch screen, axial, circumferential and diagonal register remote control, ink ductors rotation control, job memorization

- CP 2000 MasterLevel

- CP 2000 Preset Link

- CP 2000 Tandem Wash : impression cylinder washing device by CP 2000

- Preset Plus Feeder

- Head feeder 3 more suctions for paper transport

- Front sensor on flap of the feeder

- Slow down: system to slow the sheet down then 65% on feeder

- Electro mechanic shingle control

- Ultrasonic sensor double-sheet control

- Suction belt feeder with 3 sections of transport of sheets to the frontal registers

- Pneumatic side register control with integrated auto cleaning and double sheet control with direct system

- No. 2 Eltex ion blowers on feeder

- Double sheet detector – pulling device

- Ultrasonic double-sheet control

- Multiple-sheet detector/ tear-off

- Multiple sheet control/Forwarding roller

- Rear edge blowers on feeder

- Roller wash-up device controlled by CP 2000

- Modular blanket cylinder washing device by CP 2000

- Autoplate

- 5/0; 2/3 Semi-automatic Perfecting

- CombiStar: Technotrans ink temp control combined with damping refrigeration + AlcoControl

- WashStar: automatic cleaning of catch pans

- Sheed guidance guide plate cooled

- Preset Plus Delivery: a lot of preset functions and memorization, aereodinamic grippers system, slow down system by CP 2000, panel in delivery

- PowderStar Duo Plus: Grafix Exactronic Duo Plus

- DryStar 3000 CANopen: HD-IR-Plus dryer control via CANopen

- Sheet slow-down device O-ring brake

- ScrollStar: Atlas Copco compressor

- AirStar ProL central air box air cooled

- Intercom system: microphone communication system