NO LONGER AVAILABLE.

SG#165

Equipped as follows:

- Centerline system for quick job changeover

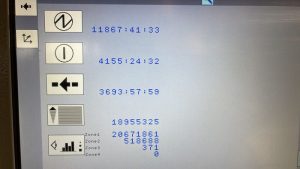

- Bobst-Electronic machine operating system CUBE 3 (Control Unit Bost Electronic) with color touch screen

- Main motor with frequency converter control

- Pile tray wit handle allowing manual lateral correction of the pile during production

- Pile lifting controlled by pressfoot

- Synchronization device timing the sheet arrival against the front lays when the machine is at a standstill

- Real pile guides (OS and OOS)

- Side blowers adjustable with Centerline marks

- Suction unit

- Safety system for lowering the pile tray

- Feed table covered with an anti-static stainless steel plate

- Feed table inlet equipped with lateral ramps

- Feed table with support plates at entry of platen station

- Feed table with 4 front lays, adjustable in pairs with front register control

- Feed table with “Pull” guide (OS) adjustable according to Centerline marks, with side register control

- Feed table with double sheet detector

- Mechanical, integrated on pull guide (OS)

- Feed table sheet-hold down device (guiding the sheets to front lays)

- Table feeder with upper frame with manual lifting devics

- Feed Table with upper transport equipment for paper, paperboard and corrugated board

- Feed table with transport belts (with lateral guidance and automatic tensionning system)

- Measurement of the cutting force with strain gauge on platen

- Pull lay operator side

- Push lay operator side, 1 D-100.002 Pull Guide (OOS) With side register control

- Pull guide adjustable according to the Centerline marks

- For jobs with opposite operator side registering, 1 D-120.002 Push Guide (OOS) Without mechanical stop (OS)

- Set of parts for changing a (OOS) “pull” guide into a “push” guide

- Adjustable centering at stripping station

- Gripper reopening device on platin

- Equipment centering and locking on platin

- Automatic locking of the chase against the upper beam on platen

- Synthetic material supporting plate on platen (Thickness 23.5 mm (0,925″)

- Quick locking device of the central stripping board on Waste Stripping Station

- Motorized lifting of the upper frame on Waste Stripping Station

- 1 central stripping quick lock

- 1 small sheet metal with compensation plate 0,4 mm or alternatively plate 0,5 mm

- 4 frames for stripping: 2 lower frames (1 for preparation meanwhile the other one is working)

- 2 frames to install the upper pull-out frame lock, 1 bar for reducing the size of the tool

- Pile tray in delivery

- Front jogger in delivery

- Adjustable rear and side joggers with Centerline marks in delivery

- Braking Brush in delivery

- Non-stop delivery with grill

- Sheet decurler for thin paper

- 2 suction pumps

- Electronic device for sheet travel control

- Control cabinet cooling unit

- 1 Cutting plate (T-120.001) Thickness 5 mm

- 1 Upper stripping equipment (T-205.001)

- Equipment required to create a waste stripping tool, including crossbars, clamps, stripper holders and stripping pins of 3, 5 and 10 mm of diameter, 1 Upper stripping pull-out frame (T-200.001), 1 Fastening equipment for stripping die (T-205.002) Including crossbars and clamps, 1 Adaption material for stripping board on the central frame (quick locking) (T-225.002), 1 Lower stripping pull-out frame (T.230.001), 1 Lower stripping equipment (T-235.001)

- Equipment for waste stripping including crossbars, pins and supports, Elevated 400 mm

- 1 G-115.001 Automatic Non-Stop belt: it is automatically introduced at the exit when the stack of sheets is finished

- The height of the evacuated pile is reduced by 150 mm, 1 B-202.001 Platform3

- Outside table for the preparation of the stripping unit