No Longer Available.

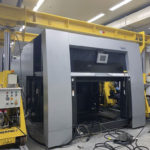

SPanthera 145 PER Autoplaten®

- Standard Equipment

- Short stroke movable platen, driven by a cam mechanism.

- WASTE STRIPPING STATION

- BLANK PILE DELIVERY STATION

- Equipment Included

- 1 B-41 Additional “CUBE” control panel

- 1 B-75 Cabinet for pump’s

- 1 C-9 Additional multidirectional lateral blowers

- 1 C-81 Lengthwise motorised movement of the suction unit

- 1 D-7 Reinforced transport equipment

- 1 E-3 Upper chase with quick locking : fixed bottom plate

- 1 E-95 Set of 20 thin plates, thickness 1mm

- 1 E-58 Perforated compensating plate

- 1 F-2 Upper pull-out frame

- 1 F-8 Lower pull-out frame

- 1 F-69 Sheet travelling control photocells

- 1 H-21 Upper pull-out frame

- 1 H-72 Long blank separating tools (151 mm)

- 1 H-78 Full sheet delivery system

- 1 M-5 Chase changer

- 1 M-11 Control table on platform

- Technical Data

- CONVERTIBLE STOCK

- Paper (depending on quality), from 80 g/m2

- Board (depending on quality), up to 2000 g/m2

- Corrugated board, up to 5 mm

- (*) Complementary equipment (D-71) for wrapped corrugated board and microflute.

- Board wrap allowed : 4% of the sheet’s width.

- Sizes

- Sheet size, max. 1450 x 1050 mm

- Sheet size, min. 580 x 450 mm

- Diecutting Size

- With gripper margin, max. 1450 x 1035 mm

- Dimension of Pallets

- Feeder / delivery, max. 1450 x 1050 mm

- Delivery, min height 150 mm

- Diecutting

- Gripper margin 9 – 17 mm

- Height of cutting rules 23.8 mm

- Width of double cuts, min. 5 mm

- Production

- Adjustable platen pressure, max. 5,5 (550 t) MN

- Production rate, up to [ sph ] 7500

- Pile Height

- Feeder : normal mode, max. 2000 mm

- Feeder : Non-Stop mode, max. 1600 mm

- Delivery : max. 1600 mm

- Fully Refurbished

- ***Pictures & Video depict equipment to move the machine***