NO LONGER AVAILABLE.

Equipped as follows:

- Circa 162 million impressions

- Sheet size 740×1040 mm

- Double coater

- Automatic sheet size adjustments

- Suction feedboard with sheet slow-down and pneumatic sidelays

- Sheet arrival control

- Suction feedboard with sheet slow-down and pneumatic sidelays

- Impression cylinder blast device

- Diagonal register remote control via Transferter

- Automatic inking-up program

- Plate inking rollers with adjustable oscillation on the run

- RCI remote controlled inking system

- Oscillation start angle adjustable from the PECOM Press Center

- Double coating module with two transfer modules and extension in delivery

- Coating module 1:Screen roller, carrying capacity 18cm3/m2, 80 lines, 1020 mm coating width standard format)

- Coating module 2:TIF screen roller, carrying capacity 25cm3/m2, 1020 mm coating width (standard format)

- Quick action palte clamps

- Blanket washing device SelectCleaning System brush.tyoe in the printing module to wash residual inks (blanket washing device without coating mode)

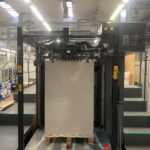

- InlineFoiler Prindor, cold foil transfer up to 5 rolls parallelLoading device for InlineFoiler Prindor

- Quick change Job, automatic job changeover sequence

- Quick change Color, Triple-Flow universal inking unit, new technology for start-stop sequences via ink flow changes, new technology for pre-setting the inking zones

- Quick Change Wash, improved ink roller washing device

- APL, fully automatic plate loading system

- Powdering device Grafix Cantronic

- Dampening water cooling device, make Technotrans “beta.d”

- Quick Change Clamp. Multi-purpose clamp bars for the coating form cylinders in both coating units

- Quick Change Clamp for frequent change of coating type in the second coating module 2xIR/TL coating interdeck dryers SelectDryer between the two coating modules (LTTLV)

- IR/TL/UV end of press dryers Roland Seccomatic for inks and dispersion coating as well as UV coating

- Nonstop equipment manual in the feeder

- Nonstop equipment semi-automatic in the delivery

- ColorPilot D + F. Densitometry plus Colorimetry ink measurement and regulation device integrated in the matching desk

- TelePresence – Service Portal

- Pintnet PrePresslink smart CIP3 connection

- Manuals and tools