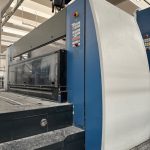

UPP#421

Equipped as follows:

- KBA Rapida five color large format offset used/pre-owned printing press

- Circa 158 million impressions

- Max paper format 1,200 x 1,620 mm.

- Min. paper size 600 x 800 mm.

- Print format 1190 x 1620 mm.

- Printable support thickness 0.1 – 1.0 mm.

- Mechanical speed 13,000c/h – Quickstart 8,000c/h

- Additional package for thin paper printing

- Antistatic in feeder, with side blowers

- Change to thin paper feeder

- Dynamic sheet brake (with extended delivery 2600mm)

- Additional package: active refrigeration control cabinet

- Refrigeration unit with main control cabinet.

- Printing plate size: 1260 x 1630 mm.

- SIS Sensoric Infeed System

- Intercom between entry and exit

- FAPC automatic plate changer including plate bender

- Drivetronic SPC – simultaneous plate change

- Drivetronic Plate Ident – not for undeveloped plates

- Ink Temperature Control

- High-tech combi refrigeration unit “betra.c”, air-cooled Technotrans

- CleanTronic Synchro

- Blanket washing device and printing cylinders for parallel washing processes for traditional inks

- 5x Drive Tronic SRW – Simultaneous Roller Washing

- 1 x Paint supply and cleaning system for dispersion paints, with connection to the pulpit, with viscosity-dependent pump performance (Harris and Bruno)

- 1 x Motorized crane for anilox roller complete with arm for delivery storage

- Non-stop roll-down

- IPA 5% reduction incl. Technotrans “beta.f” microfilter

- Alcoprint 4000

- KBA VariDry IR/ hot air outlet and extended delivery ALV2

- WALLSCREEN for viewing machine processes

- ErgoTronic

- ErgoTronic ColorControl – Automatic XY ink density measurement at the pulpit

- ErgoTronic Lab – Color measurement and control according to Lab values

- QualiTronic ColorControl – Inline density measurement

- Feeder Drivetronic

- Selection of format from Ergotronic pulpit

- Ultrasonic double sheet control

- optical control of oblique sheets

- blanket cylinder, plate, print, coated with hardened and anti-corrosion surface

- all adjustments by Ergotronic pressure, paper thickness, registers

- axial and radial register adjustment +/-1.0mm, diagonal +/- 0.30mm.

- plate cylinder detachable from the blanket cylinder

- Venturi air sheet guide, all adjustments by Ergotronic

- dampening Varidamp

- pluggable / disengageable inking unit by ErgoTronic – stationary rollers

- fully automatic roller washing device programmable from the pulpit

- power supply to the KBA Easy Pump electric membrane coating pump

- touch display in delivery

- powdery spray Grafix Powdermax

- air supply cabinet with electronic regulation

- Ergotronic pulpit

Complete with all standard parts and accessories